|

|

WPI Technical Theatre Handbook: Lighting Boards |

|

||

|

Next: Control Up: Lighting Previous: Cables and Connectors Contents Index Lighting BoardsThe lighting board is what the M.E. or L.D. uses to run the lights for a production. Many different styles of boards exist, with a wide range of capabilities and features. Portable lighting boards are actually a fairly recent concept. Early systems required the controls for dimming the instruments to be part of the dimmers due to mechanical limitations. Within the past twenty years or so, schemes for running the dimmers remotely have been developed, some of which are discussed in detail in the next section. These innovations have helped to bring about the creation of separate lighting boards. The simplest lighting board one is likely to find today allows the operator to set up two scenes and cross-fade between them. These are commonly referred to as X-Y boards. An X-Y board has a number of channels associated with it, where each channel can control one or more dimmer channels. For example, twelve channels may be controlled with a small board. Levels can be set for each of these individual channels on two scenes (the X and Y scenes). A cross-fader allows switching between scenes -- as one scene comes up, the other goes down, and vice versa. One scene is generally in use at a time. While the other scene is inactive, it can be pre-set for the next scene, which is generally done from a sheet of paper with the appropriate levels written on it.

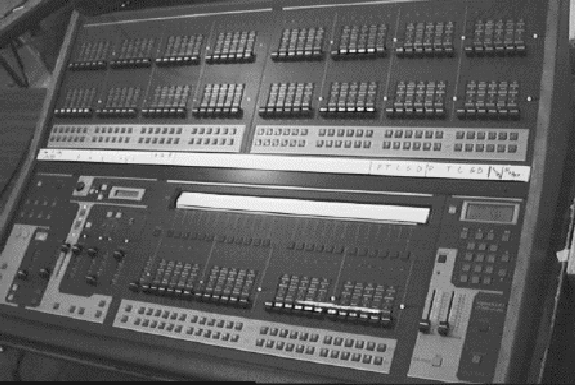

Most boards also allow some form of soft patching, meaning assigning more than one individual dimmer channel to a board channel. This is advantageous because each dimmer channel is rated for a maximum power handling capability. Soft patching allows more instruments to be controlled as a logical unit than a single dimmer channel allows. Older lighting boards use a matrix of diode pins to electrically connect board channels to dimmer channels. Modern boards tend to accomplish the same task through the use of software. Advanced lighting boards usually provide all of the same features as an X-Y board, but add the ability to store scenes, record a sequence of scenes in a cue stack, and record light chases. Scene storage is an especially handy feature because it becomes increasingly difficult to set an entire scene when the number of channels on a board is high. With a standard X-Y board, every fader in a scene has to be set to a level recorded on a piece of paper. Scene storage boards remove this hassle by allowing the operator to record a scene and assign it to a single fader. More advanced boards allow these recorded scenes to be strung together into what is commonly known as a cue stack. This enables the operator to simply push a ``go'' button to advance to the next lighting cue. Lastly, some boards allow repeating sequences of scenes to be run. Most are outfitted with a speed control that allows the operator to adjust how quickly the sequence progresses. Some boards even provide an input for an audio synchronization signal, such that lighting chases may be synchronized with an audio track. See figures 5.19 and 5.20 for examples of advanced lighting boards.

Next: Control Up: Lighting Previous: Cables and Connectors Contents Index Steve Richardson 2000-07-06 Use of information in this document implies understanding and agreement with the copyright and terms of use. Specifically, no warranty is expressed or implied regarding the accuracy of the information contained within. YOU USE THIS INFORMATION AT YOUR OWN RISK. All trademarks are property of their respective owners. You must obtain permission from the author before using the contents of The Handbook for anything other than private use. |

Table of Contents

| |||