|

|

WPI Technical Theatre Handbook: Counterweighted Fly Systems |

|

|

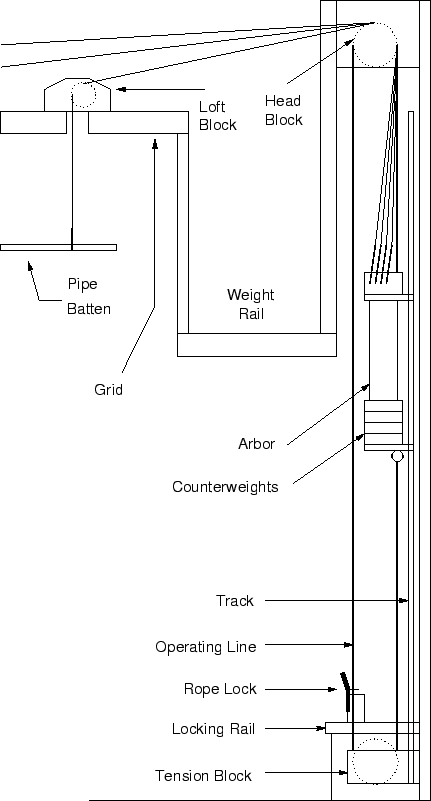

Next: Lifts Up: Fly Methods Previous: Non-Counterweighted Pulley Systems Contents Index Counterweighted Fly SystemsThe major disadvantages to non-counterweighted fly systems are that they require more than one person to operate, they require a lot of work to use, and they are unsafe. Most modern theatres are equipped with what is known as a counterweighted fly system. This type of fly system makes flying battens significantly easier and safer, and allows for one person operation in most cases. Counterweight fly systems are rather complex, and there exist entire documents devoted to their design, construction, and operation. Only a basic introduction to the components and operating techniques will be given here. Anyone operating a fly system should have appropriate training from a competent fly person. The basic principle behind counterweight fly systems is that a pulley system and counterweight mass are used to make the job of moving a heavily loaded batten easier on the fly operator. This mass may be adjusted for the amount of load on the batten, thus providing for a fairly consistent feel on the operating lines. Extremely heavy objects can be flown with relative ease, as long as the appropriate counterweights are used.

There are two key working positions to be aware of. Most operation for running a show occurs at the locking rail, which is at stage level. From this position, battens can be flown in and out in a safe fashion by a single fly operator. To raise or lower a properly weighted fly batten, the operator simply needs to release the rope lock and raise or lower the operating line. In addition to working at the locking rail, it is necessary to work from the weight rail to load or unload (or strip) counterweights onto the arbor when a batten is flown in and weight is being added or removed. Refer to figure 4.5 for a diagram that shows the components of a counterweight fly system. Each empty pipe batten has weight, and therefore counterweights must be added to the arbor for that batten. Any additional objects flown from the batten will require that additional weights be placed on the arbor. To aid in distinguishing between the pipe weight and the additional weight on an arbor, two plates that rest on top of the weights are used. The first plate stays on top of the initial pipe weight load. The second plate rests on top of any additional weight that is added, directly below the locking collars that secure the weights. When stripping weights, it is customary to take off only the additional weight, leaving the pipe weights.

It is sometimes necessary to work with an unbalanced line. This problem generally occurs when hard scenery is flown from a batten, or when a scrim, cyclorama, or other soft goods are flown. The problem occurs with hard scenery because the batten can not be flown into a convenient position for weight loading. There are two ways to handle this problem. One method involves muscling the scenery to the grid, and braking the operating lines with a piece of pipe. With the scenery gridded, the arbor for the batten is resting on the ground, thus the appropriate weights may be added. Another method involves laying the piece of scenery down on the ground so that the batten may be fully flown in. While the batten is flown in, counterweights may be added from the weight rail. Additional weight must be added to the batten for the duration of weight loading. Typically this is accomplished by having crew members hold on to the batten while weight is loaded. It should be made clear that in some cases this isn't always a safe option, especially when heavy scenery is being flown. Another problem occurs when flying soft goods. While the batten may be fully flown in and weighted correctly, the nature of soft goods are such that an imbalanced load is placed on the batten as they are flown in and out. Their full weight is only distributed on the batten when they are fully flown out. In the intermediate time while they are being flown in or out, they are piled up on the ground, leaving an imbalanced batten. Typically this is handled by keeping the line counterweighted for the full weight of the piece being flown, and paying extra care when flying the batten in or out. The batten will have a tendency to come crashing to the ground as it is brought in, and will require some muscling to fly it out. There are many issues to consider when working with counterweight fly systems. Some of these are listed below:

Next: Lifts Up: Fly Methods Previous: Non-Counterweighted Pulley Systems Contents Index Steve Richardson 2000-07-06 Use of information in this document implies understanding and agreement with the copyright and terms of use. Specifically, no warranty is expressed or implied regarding the accuracy of the information contained within. YOU USE THIS INFORMATION AT YOUR OWN RISK. All trademarks are property of their respective owners. You must obtain permission from the author before using the contents of The Handbook for anything other than private use. |

Table of Contents

| |