|

|

WPI Technical Theatre Handbook: Chain Motors |

|

||

|

Next: Flying Set Pieces Up: Fly Methods Previous: Lifts Contents Index Chain Motors

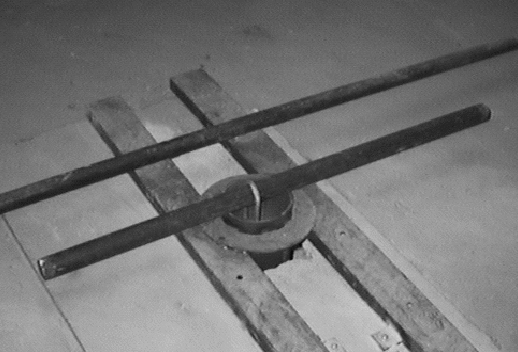

While lifts provide a fairly effective means to fly equipment, they have several downfalls. For one, they are typically large and quite heavy. If used in pairs, two to three people are required to operate them safely. Safety issues aside, they are simply inconvenient in a lot of situations. Lastly, lifts take up a lot of floor space. In typical theatrical uses, the ideal placement of the lift conflicts with house seating. These are all areas that the chain motor excels in. If appropriate load-bearing hang points are available in a venue (as they are in WPI's Alden Hall), the simplicity and convenience of chain motors makes them an ideal solution for flying lighting trusses and other equipment. A chain motor is simply a large electric motor with a gearbox and a chain drive mounted in one chassis. The chassis of the motor generally has a large hook mounted on its underside, to which loads are attached. An extremely heavy gauge chain with a hook at one end passes through the motor and into a chain bag. The hook of this chain is generally clipped to the shackle of a wire rope sling, which is attached to a load-bearing overhead beam. Once the attachment has been made to an overhead hang point, the motors can have loads attached for flying. Several methods exist for the control of the chain motors. The simplest method uses handheld controls (sometimes called pickles) to raise and lower the motors. Complex computer-controlled systems exist for automatic flying of equipment. These systems can control dozens of motors simultaneously. Systems this complex are not generally necessary for a small number of chain motors. At WPI, a pair of chain motors with handheld controls are often used to fly lighting truss. The most common venue for this is Alden Hall, where several sets of hang points exist for such a purpose. The following list of instructions should be followed for proper use of the chain motors:

While working with chain motors are fairly straightforward, there are several points one should be concerned with when working with them:

Next: Flying Set Pieces Up: Fly Methods Previous: Lifts Contents Index Steve Richardson 2000-07-06 Use of information in this document implies understanding and agreement with the copyright and terms of use. Specifically, no warranty is expressed or implied regarding the accuracy of the information contained within. YOU USE THIS INFORMATION AT YOUR OWN RISK. All trademarks are property of their respective owners. You must obtain permission from the author before using the contents of The Handbook for anything other than private use. |

Table of Contents

| |||