|

|

WPI Technical Theatre Handbook: Thimbles, Wire Rope Clips, and Swages |

|

|

|

Next: Shackles, Turnbuckles and Hooks Up: Common Rigging Hardware Previous: Wire Rope Contents Index Thimbles, Wire Rope Clips, and Swages

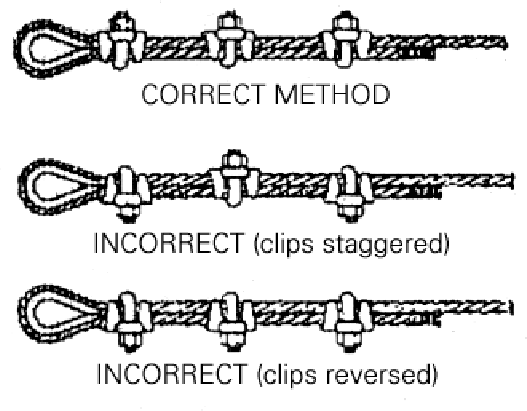

When working with wire rope, it is extremely important that several guidelines are followed with regards to termination. Any time the wire rope needs to be attached to a hang point that would cause the cable to sharply bend, a device called a thimble must be used. Thimbles simply guide the cable into a natural curve shape and offer a degree of protection to the cable in the loop. To secure the end of the rope, wire rope U-clips are used. These clips provide an effective means for terminating cables, but must be used properly to be fully effective. Figure 4.3 shows correct and incorrect methods for applying these clips. The correct sequence for applying U-clips to a piece of wire rope are described below:

Another method for securing the ends of wire rope is through the use of swages, or nicopress sleeves. Small metal sleeves are pressed on to the wire rope with a special tool. These sleeves are permanent, but act much in the same way that clips do. When properly applied, swages can hold the full rated working load of the cable they are attached to.

Next: Shackles, Turnbuckles and Hooks Up: Common Rigging Hardware Previous: Wire Rope Contents Index Steve Richardson 2000-07-06 Use of information in this document implies understanding and agreement with the copyright and terms of use. Specifically, no warranty is expressed or implied regarding the accuracy of the information contained within. YOU USE THIS INFORMATION AT YOUR OWN RISK. All trademarks are property of their respective owners. You must obtain permission from the author before using the contents of The Handbook for anything other than private use. |

Table of Contents

| ||