|

|

WPI Technical Theatre Handbook: Lifts |

|

|

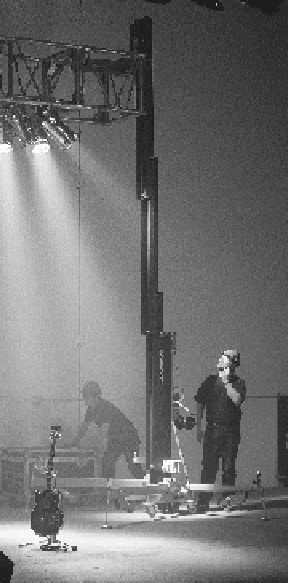

Next: Chain Motors Up: Fly Methods Previous: Counterweighted Fly Systems Contents Index LiftsOften times, a fly system is not available for use for flying lighting or audio equipment. Some venues, such as WPI's Alden Hall, do not have any permanent provisions for lighting equipment in the house. Thus, it becomes desirable to be able to fly a lighting truss in front of the proscenium by some portable means. Several companies produce portable lifts that can be raised and lowered by manual, pneumatic, hydraulic, or electric means. Lifts go by several names, such as Genie Lifts (a trade name) or towers. One such lift is shown in figure 4.7. Lifts have a set of feet that are adjusted to give stability to the structure. These feet typically immobilize the lift, as well as increase the footprint to reduce the chances of tipping. Once the feet are in position, the lift is typically raised enough for the load to be placed on it. Once loaded, they can be raised to the appropriate height for the task.

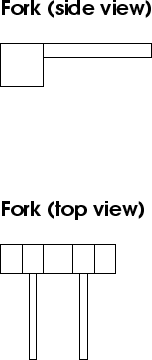

Usually lifts have a set of forks, akin to a forklift, for bearing a load. When placing a load on these forks, the load should be placed as close to the lift end of the fork as possible, to minimize the amount of stress on the fork. Often, two lifts are used in conjunction to raise a span of truss. When this is the case, it often helps to have a person stand back and keep watch over how level the truss is. Hand signals are typically used to tell the people raising the truss to stop or go.

At WPI, Genie Lifts are often used to fly lighting truss. There are several important things to consider when using these lifts, as listed below:

Next: Chain Motors Up: Fly Methods Previous: Counterweighted Fly Systems Contents Index Steve Richardson 2000-07-06 Use of information in this document implies understanding and agreement with the copyright and terms of use. Specifically, no warranty is expressed or implied regarding the accuracy of the information contained within. YOU USE THIS INFORMATION AT YOUR OWN RISK. All trademarks are property of their respective owners. You must obtain permission from the author before using the contents of The Handbook for anything other than private use. |

Table of Contents

| |